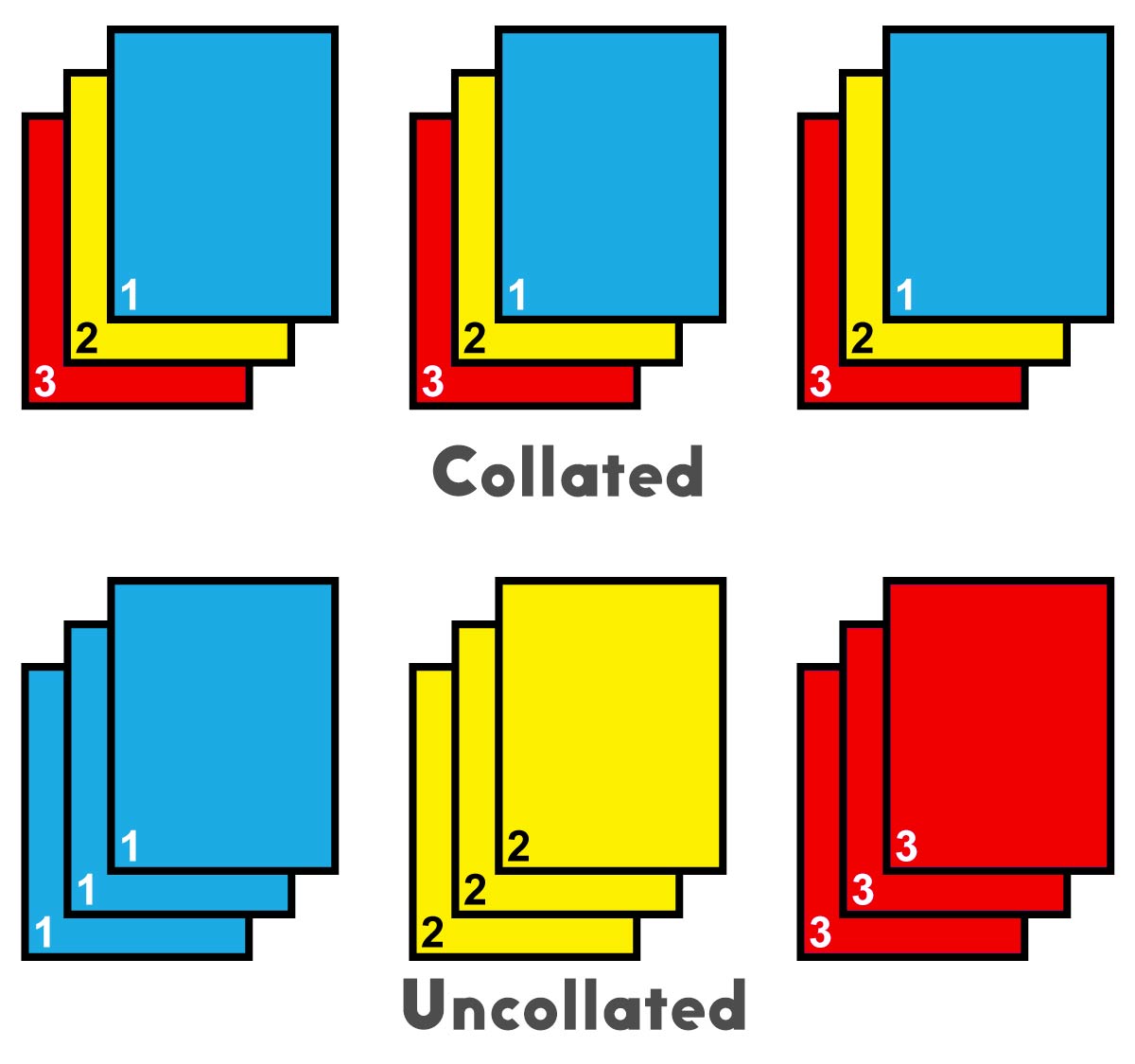

What does collated mean printing – What does collated mean in printing? Collating is a crucial step in the printing process that involves gathering and arranging printed sheets in the correct order to create a complete document. This guide will delve into the world of collating, exploring its methods, equipment, and applications.

Collating ensures that the pages of a document are assembled in the intended sequence, making it easy for readers to navigate and understand the content. Whether it’s a simple booklet or a complex report, proper collation is essential for creating a professional and polished final product.

Collating in Printing Processes

Collating is a post-press process in printing that involves gathering and assembling individual printed sheets in the correct sequence to create a complete document or publication. It ensures that the pages are arranged in the intended order, making the printed material readable and usable.

In offset printing, collating is typically achieved using a collating machine. This machine has multiple stations, each of which holds a stack of printed sheets. The sheets are then fed into the machine, and the machine automatically gathers and assembles them in the correct order.

The collated sheets are then ejected from the machine and stacked or bound into a finished product.

In digital printing, collating can be achieved using a variety of methods. One common method is to use a digital finisher. This machine can perform a variety of post-press tasks, including collating, stapling, and binding. Another method is to use a software program to create a collated PDF file.

This file can then be printed on a digital press, and the collated sheets can be ejected from the press and stacked or bound into a finished product.

Collating offers several benefits in printing. It ensures that the printed sheets are assembled in the correct order, making the printed material readable and usable. It also reduces the risk of errors, as the machine can automatically gather and assemble the sheets without human intervention.

Additionally, collating can help to improve the overall quality of the printed product, as it can help to prevent smudging or misalignment of the sheets.

However, there are also some limitations to collating. It can be a time-consuming process, especially for large print runs. Additionally, it can be expensive to purchase and maintain a collating machine. As a result, collating is typically only used for high-volume print runs or for printed materials that require a high level of accuracy.

Types of Collating Methods

Collating is an essential step in the printing process, as it ensures that the pages of a document are assembled in the correct order. There are several different collating methods available, each with its own advantages and disadvantages.

The most common collating methods include:

- Saddle stitching

- Perfect binding

- Spiral binding

- Wire-O binding

- Comb binding

- Loose-leaf binding

Saddle Stitching

Saddle stitching is a simple and cost-effective collating method that is often used for booklets and magazines. It involves stapling the pages together at the spine. Saddle stitching is relatively inexpensive and easy to do, but it is not as durable as some other collating methods.

Perfect Binding

Perfect binding is a more durable collating method than saddle stitching. It involves gluing the pages together at the spine, which creates a strong and secure bond. Perfect binding is often used for books and reports.

Spiral Binding

Spiral binding is a versatile collating method that can be used for a variety of documents, including presentations and manuals. It involves punching holes along the spine of the pages and then inserting a spiral coil through the holes. Spiral binding allows the document to be opened flat, which makes it easy to read and reference.

Wire-O Binding

Wire-O binding is a similar to spiral binding, but it uses a double-loop wire instead of a spiral coil. Wire-O binding is often used for calendars and planners.

Comb Binding

Comb binding is a good option for documents that need to be updated frequently. It involves punching holes along the spine of the pages and then inserting a plastic comb through the holes. Comb binding allows the pages to be easily removed and replaced.

Loose-Leaf Binding

Loose-leaf binding is the least durable collating method, but it is also the most flexible. It involves punching holes along the spine of the pages and then inserting them into a binder. Loose-leaf binding allows the pages to be easily removed and rearranged.

Collating Equipment and Machinery

Collating equipment plays a crucial role in the printing process, ensuring the proper assembly and sequencing of printed materials. Various types of collating equipment are available, each with specific functions and capabilities.

Types of Collating Equipment

1. Manual Collators

Manual collators require human operators to gather and assemble printed sheets manually. They are suitable for small-volume or short-run printing jobs where accuracy and precision are paramount.

2. Semi-Automatic Collators

Semi-automatic collators combine manual and automated processes. They feature a conveyor system that transports printed sheets to a gathering station, where operators manually assemble them. These machines offer higher speed and efficiency than manual collators.

3. Fully Automatic Collators

Fully automatic collators are highly sophisticated machines that automate the entire collating process. They use advanced sensors and software to gather and assemble printed sheets accurately and quickly. These machines are ideal for high-volume printing jobs where speed and efficiency are essential.

Factors to Consider When Choosing Collating Equipment

The choice of collating equipment depends on several factors, including:* Volume of printed materials:The number of sheets to be collated determines the capacity and speed required from the equipment.

Sheet size and weight

Different collators are designed to handle specific sheet sizes and weights, so it’s crucial to choose equipment compatible with the materials being printed.

Accuracy and precision

The level of accuracy and precision required for the collated materials influences the type of equipment needed.

Speed and efficiency

The speed and efficiency of the collating process are important considerations, especially for high-volume printing jobs.

Budget

The cost of collating equipment varies depending on its capabilities and features, so it’s essential to consider the budget available.

Collating for Different Paper Sizes and Formats

Collating for different paper sizes and formats presents unique challenges. Here are the key aspects and solutions to consider:

Challenges in Collating Non-Standard Paper Sizes

- Misalignment and stacking issues due to variations in paper dimensions.

- Difficulty in handling and feeding non-standard sizes into collating machines.

- Increased risk of paper jams and damage during the collating process.

Solutions for Collating Different Paper Sizes

To address these challenges, several solutions have been developed:

- Custom Collating Machines:Machines designed specifically for non-standard paper sizes, with adjustable guides and feeding mechanisms.

- Manual Collating:Collating by hand, which requires careful alignment and stacking of different paper sizes.

- Software Solutions:Software that adjusts the collating sequence to accommodate different paper sizes, ensuring proper alignment.

Best Practices for Collating Different Paper Formats

To ensure efficient and accurate collating, consider the following best practices:

- Use consistent paper sizes and formats throughout the document.

- If non-standard paper sizes are necessary, invest in custom collating machines or seek professional manual collating services.

- Use software solutions to automate the collating process and minimize errors.

- Ensure proper alignment and stacking of different paper sizes before collating.

- Monitor the collating process closely to identify and address any issues promptly.

Collating for Perfect Binding

In perfect binding, collating plays a crucial role in ensuring the proper assembly and durability of the finished product. Perfect binding involves adhering the spine of the document to a flexible adhesive, which requires precise alignment and organization of the printed pages.

Specific Requirements for Collating Documents for Perfect Binding

To achieve optimal results, specific requirements must be met during the collating process for perfect binding:

- Page Order:The pages must be arranged in the correct sequence, as any deviation will result in a misaligned or defective document.

- Spine Alignment:The pages must be aligned perfectly along the spine to ensure proper adhesion and prevent tearing or creasing.

- Page Orientation:All pages must be consistently oriented in the same direction, as incorrect orientation will lead to misalignment or printing errors.

- Page Margins:Sufficient margins must be maintained to allow for proper trimming and binding without compromising the printed content.

- Spine Preparation:The spine of the document may require scoring or roughening to enhance adhesion and prevent the pages from separating.

Quality Control Measures for Perfect Binding Collation

To ensure the quality and accuracy of the collating process for perfect binding, several quality control measures are necessary:

- Visual Inspection:A thorough visual inspection of the collated documents can identify any errors in page order, alignment, or orientation.

- Spine Alignment Verification:Using a spine alignment tool or gauge, the alignment of the pages along the spine can be checked to ensure accuracy.

- Page Count Verification:The total number of pages in the document should be verified against the specified page count to ensure completeness.

- Sample Binding:A small sample of the collated documents can be bound to assess the overall quality of the binding and identify any potential issues.

Collating for Saddle Stitching

Collating plays a crucial role in saddle stitching, a binding method that involves stapling sheets together along the spine. Proper collation ensures that the pages are in the correct order and orientation for accurate binding.

Specific Requirements for Collating Documents for Saddle Stitching

Page Order

The pages must be arranged in the correct sequence, with the front cover on top and the back cover on the bottom.

Page Orientation

All pages should be oriented in the same direction, either portrait or landscape.

Page Alignment

The pages should be aligned evenly, ensuring that the top and bottom edges are flush.

Sheet Count

The total number of sheets in each collated set must match the intended page count of the finished document.

Quality Control Measures for Proper Collation

Visual Inspection

Manually checking the order and orientation of pages before stitching.

Automatic Collating Machines

Using machines that automatically detect and correct collation errors.

Test Stitching

Stitching a small batch of collated sheets to verify the accuracy before proceeding with the entire run.

Step-by-Step Guide to Collating Documents for Saddle Stitching

- Gather all the pages required for the document.

- Arrange the pages in the correct order, with the front cover on top and the back cover on the bottom.

- Align the pages evenly, ensuring that the top and bottom edges are flush.

- Check the sheet count to ensure it matches the intended page count.

- Visually inspect the pages for any errors in order or orientation.

- If necessary, use an automatic collating machine to correct any errors.

- Test stitch a small batch of collated sheets to verify accuracy.

Table: Key Requirements for Collating Documents for Saddle Stitching

| Requirement | Description ||—|—|| Page Order | Pages arranged in the correct sequence || Page Orientation | All pages oriented in the same direction || Page Alignment | Pages aligned evenly || Sheet Count | Number of sheets matches the intended page count || Quality Control | Visual inspection, automatic machines, test stitching |

Script to Automate Collating Process for Saddle Stitching

“`import pandas as pdimport numpy as np# Read data from a CSV file containing page order and orientationdata = pd.read_csv(‘page_order.csv’)# Create a function to collate pagesdef collate_pages(pages): # Sort pages by page number pages = pages.sort_values(‘page_number’) # Check for errors in page order and orientation for i in range(1, len(pages)): if pages[‘page_number’][i] != pages[‘page_number’][i-1] + 1: raise ValueError(‘Error: Page order is incorrect.’) if pages[‘orientation’][i] != pages[‘orientation’][i-1]: raise ValueError(‘Error: Page orientation is incorrect.’) # Collate pages in the correct order collated_pages = pages[‘page_content’].tolist() return collated_pages# Collate pages using the functioncollated_pages = collate_pages(data)# Save the collated pages to a filewith open(‘collated_pages.pdf’, ‘wb’) as f: f.write(collated_pages)“`

Collated printing refers to the process of assembling multiple pages of a document in the correct order. To ensure accurate collation, it’s essential to identify the printer’s IP address. You can find the IP address by following the steps outlined in where to find ip address on printer.

Once the IP address is obtained, you can proceed with the collation process, ensuring that the printed documents are in the intended sequence.

Visual Representation of Collating Process for Saddle Stitching

[Image of a collating machine aligning and stacking pages in the correct order for saddle stitching]

Collating for Wire-O Binding

Collating plays a crucial role in wire-o binding, a binding method that involves inserting a wire-o element through a series of holes punched along the edge of the document. Proper collation ensures that the pages are arranged in the correct order and orientation, resulting in a cohesive and professional-looking finished product.

Specific requirements for collating documents for wire-o binding include:

Paper Orientation and Alignment

- All pages must be aligned with the same orientation, either portrait or landscape.

- The pages should be stacked evenly, with no gaps or overlaps.

Page Order and Sequence

- The pages must be arranged in the correct sequential order, as per the intended layout of the document.

- Any inserts, such as covers or dividers, should be placed in their designated positions.

Number of Pages per Section

- Documents with multiple sections, such as chapters or parts, should be collated separately and then combined in the final assembly.

- The number of pages per section should be consistent, ensuring that the wire-o element can be inserted without causing damage to the binding.

Quality Control Measures

- Visual inspection:Manually checking the collated pages for errors in order, orientation, or alignment.

- Mechanical counting:Using a mechanical counter to verify the number of pages in each section.

- Automated verification systems:Employing specialized software or machines to automatically detect and correct collation errors.

Consequences of Improper Collation

Improper collation can lead to several problems with the finished product, including:

- Misaligned pages, making the document difficult to read.

- Incomplete sections, missing important content.

- Damage to the binding, causing pages to fall out.

Tips and Best Practices

- Use gathering guides to ensure proper alignment and stacking of the pages.

- Employ collating machines for efficient and accurate collation, especially for large volumes.

- Double-check the collation before binding to minimize errors.

Collating for Loose-Leaf Binding

Collating plays a crucial role in loose-leaf binding, ensuring that documents are organized and presented in the correct order. It involves gathering, sorting, and arranging individual sheets or pages into a cohesive set, ready for insertion into a loose-leaf binder.

Specific Requirements for Collating Loose-Leaf Documents

- Page Order and Orientation:Documents must be collated in the correct sequence and with the proper page orientation (portrait or landscape) to maintain readability and logical flow.

- Hole Punching and Margin Alignment:Collated documents require precise hole punching to align with the binder’s rings. Margins must be consistent to ensure proper alignment and presentation.

- Cover Page and Back Matter:Collation includes the front and back covers, as well as any additional pages such as a table of contents or index, in the correct order.

Quality Control Measures for Loose-Leaf Collation

Ensuring proper collation is critical for loose-leaf binding. Quality control measures include:

- Visual Inspection:Manual inspection of collated documents to verify page order, hole alignment, and completeness.

- Automated Collation Machines:Machines that automatically collate documents, reducing errors and increasing efficiency.

- Document Tracking Systems:Tracking systems that monitor the progress of collated documents, ensuring timely completion and accuracy.

Procedure for Collating Documents for Loose-Leaf Binding

Materials:

- Documents to be bound

- Loose-leaf binder

- Hole punch

Steps:

- Gather Materials:Collect all necessary documents and materials.

- Sort and Organize Documents:Arrange documents in the correct order and orientation.

- Hole Punch and Align:Punch holes in the documents and align them precisely with the binder’s rings.

- Insert Documents into Binder:Insert the collated documents into the binder, ensuring they are facing the correct direction.

- Quality Control:Visually inspect the collated documents to verify accuracy and completeness.

Collating for Presentation Folders

Collating plays a vital role in assembling presentation folders, ensuring the proper order and organization of documents. It involves gathering and arranging various materials, such as cover pages, presentation sheets, handouts, and other relevant documents, into a cohesive set.

The specific requirements for collating documents for presentation folders depend on the purpose and design of the folder. Typically, it involves:

- Determining the correct sequence of documents based on the intended flow of information.

- Ensuring all necessary documents are included and none are missing.

- Maintaining the proper orientation of documents (e.g., portrait or landscape).

- Positioning documents within the folder pockets or compartments in a logical and visually appealing manner.

Quality Control Measures

To ensure proper collation for presentation folders, quality control measures are crucial:

- Visual Inspection:Manually checking the order, completeness, and orientation of documents.

- Automated Collation Systems:Using machines that automatically gather and arrange documents based on pre-defined parameters.

- Verification Checklists:Creating and using checklists to ensure all necessary documents are included and in the correct order.

Troubleshooting Collating Issues

Collating issues can arise during the printing process, leading to misaligned or incomplete sets of documents. Understanding common issues and their causes is crucial for effective troubleshooting and resolving these problems efficiently.

Identifying Common Collating Issues and Causes

| Issue | Cause | Resolution |

|---|---|---|

| Misaligned pages | Incorrect paper alignment in the collator | Adjust the paper guides or tray settings to ensure proper alignment. |

| Missing pages | Paper jam or malfunctioning sensors | Clear the paper jam or replace the faulty sensors. |

| Incomplete sets | Collator malfunction or incorrect settings | Inspect the collator for any mechanical issues or reconfigure the settings according to the desired sequence. |

| Pages out of order | Incorrect paper feeding or software error | Check the paper feed mechanism and ensure the software is configured to the correct collation order. |

| Blank pages | Paper loading errors or defective paper | Reload the paper properly or replace the defective paper with fresh sheets. |

Automation in Collating

Automation plays a crucial role in modern collating processes, significantly enhancing efficiency, productivity, and accuracy. Automated collating systems have become indispensable for businesses that handle large volumes of documents, such as print shops, mailing houses, and data centers.

There are several types of automated collating systems available, each designed to meet specific requirements. These systems include:

Flat Sheet Collators

Flat sheet collators are used for collating single sheets of paper. They can handle various paper sizes and weights, making them suitable for a wide range of applications, including brochures, manuals, and presentations.

Saddle Stitchers

Saddle stitchers are used for collating and stapling booklets and magazines. They can produce high-quality booklets with professional-looking spines.

Collating in printing refers to the process of gathering and arranging printed pages in a specific order. When printing , collating ensures that the pages are assembled in the correct sequence, typically based on page numbers or other designated criteria.

This process is essential for producing organized and complete printed documents, such as booklets, reports, or presentations.

Perfect Binders, What does collated mean printing

Perfect binders are used for collating and binding books with a glued spine. They produce durable and long-lasting books, making them ideal for high-volume printing.

Wire-o Binders

Wire-o binders are used for collating and binding documents with a wire-o spine. They allow for easy page turning and are often used for presentations, manuals, and reports.

Benefits of Automated Collating

- Increased efficiency and productivity: Automated collating systems can process large volumes of documents quickly and accurately, freeing up manual labor for other tasks.

- Reduced labor costs: Automation eliminates the need for manual labor, reducing labor costs and increasing profitability.

- Improved accuracy and consistency: Automated systems ensure that documents are collated correctly and consistently, reducing errors and improving the quality of the final product.

- Ability to handle large volumes of documents: Automated collating systems can handle large volumes of documents, making them suitable for high-volume printing environments.

Limitations of Automated Collating

- High initial investment cost: Automated collating systems can be expensive to purchase and install, requiring a significant initial investment.

- Requires specialized training to operate: Automated collating systems require specialized training to operate, which can be time-consuming and costly.

- May not be suitable for small-volume or short-run jobs: Automated collating systems may not be cost-effective for small-volume or short-run jobs, as manual collating may be more efficient.

Quality Control in Collating

Quality control is crucial in collating processes to ensure the accuracy, completeness, and overall quality of the final product. By implementing stringent quality control measures, businesses can minimize errors, maintain high standards, and enhance customer satisfaction.

Various quality control measures are employed in collating processes, including:

Visual Inspection

- Manual inspection of collated sets to verify the correctness of page order, orientation, and completeness.

- Using magnifying glasses or specialized equipment to examine fine details and identify potential defects.

Automated Verification

- Employing barcode scanners or optical character recognition (OCR) technology to automatically check page sequences and identify missing or duplicated pages.

- Utilizing sensors to detect misaligned or damaged pages during the collating process.

Statistical Process Control

- Monitoring and analyzing collating processes using statistical methods to identify trends, variations, and potential areas for improvement.

- Implementing control charts to track key performance indicators (KPIs) and ensure consistent quality.

Best Practices for Ensuring High-Quality Collation

- Establish clear and detailed collating specifications to guide the process.

- Train and certify operators on proper collating procedures and quality control techniques.

- Regularly calibrate and maintain collating equipment to ensure accuracy and precision.

- Implement a comprehensive quality control system that includes both manual and automated checks.

- Continuously monitor and improve collating processes based on feedback and data analysis.

Collating as a Value-Added Service

Collating can be a valuable service that print shops can offer to their customers. It can save customers time and money, and it can help to ensure that their printed materials are accurate and professional-looking.There are several benefits to offering collating services to customers.

First, it can save them time. Collating is a time-consuming process, especially for large documents. By outsourcing this task to a print shop, customers can free up their time to focus on other important tasks.Second, collating can save customers money.

Print shops can often collate documents more efficiently than customers can, which can result in cost savings. Additionally, collating can help to reduce the risk of errors, which can also save customers money in the long run.Third, collating can help to ensure that printed materials are accurate and professional-looking.

A well-collated document is easy to read and navigate, and it makes a good impression on recipients.Print shops that offer collating services should market and promote their services to potential customers. This can be done through a variety of channels, such as online advertising, social media, and email marketing.

It is important to target the right audience for collating services. The best target audience for these services is businesses that produce large volumes of printed materials, such as marketing agencies, law firms, and schools.The following table summarizes the key benefits and target audience for collating services:| Benefit| Target Audience||—|—|| Time savings | Businesses that produce large volumes of printed materials || Cost reductions | Businesses that produce large volumes of printed materials || Improved accuracy | Businesses that produce large volumes of printed materials |Here is a sample marketing email promoting collating services to potential customers:“`Subject: Save Time and Money with Our Collating Services!Dear [Customer Name],Are you tired of spending hours collating documents?

Let us help you save time and money with our professional collating services.We offer a variety of collating services to meet your needs, including:* Document collating

- Booklet collating

- Presentation folder collating

- And more!

Our collating services are fast, accurate, and affordable. We can collate documents of any size or format, and we can even handle complex collating jobs.Contact us today to learn more about our collating services. We would be happy to answer any questions you have and provide you with a free quote.Sincerely,[Your Name]“`

Expert Answers: What Does Collated Mean Printing

What is the purpose of collating in printing?

Collating ensures that the pages of a printed document are assembled in the correct order, making it easy for readers to navigate and understand the content.

What are the different types of collating methods?

Common collating methods include saddle stitching, perfect binding, spiral binding, wire-o binding, comb binding, and loose-leaf binding.

What factors should be considered when choosing a collating method?

Factors to consider include cost, durability, appearance, and suitability for different types of documents.

How can businesses improve the efficiency and accuracy of their collating processes?

Automation and quality control measures can help businesses streamline their collating operations and minimize errors.

What are the benefits of offering collating services to customers?

Collating services can save customers time, reduce costs, and improve the accuracy and professionalism of their printed documents.