What is utilization? It’s a fundamental concept that pervades various fields, from engineering to economics. It refers to the extent to which a resource or asset is being used. Understanding utilization is crucial for optimizing efficiency, reducing costs, and maximizing productivity.

In this exploration, we will delve into the intricacies of utilization, examining its types, significance, and factors that influence it. We will also explore strategies for improving utilization and its applications in diverse domains, ranging from project management to healthcare.

Define utilization: What Is Utilization

Utilization refers to the act of using something to its full potential or capacity. It involves employing resources, assets, or opportunities to achieve specific goals or objectives.

In the context of economics, utilization often refers to the efficient use of resources, such as labor, capital, and raw materials, to maximize production and minimize waste. For example, a manufacturing company may strive to optimize the utilization of its machinery to increase output and reduce downtime.

In the field of healthcare, utilization refers to the use of healthcare services, such as doctor visits, hospital stays, and prescription medications. Healthcare providers analyze utilization patterns to identify areas where services can be used more effectively or efficiently, leading to better patient outcomes and reduced costs.

In environmental science, utilization refers to the sustainable use of natural resources, such as water, land, and energy. It involves finding ways to meet human needs while preserving the environment for future generations. For example, farmers may employ water-efficient irrigation techniques to reduce water utilization and conserve this precious resource.

Utilization, in the context of an apartment, encompasses the essential services and amenities that contribute to the comfort and functionality of a living space. These utilities, as discussed in what are utilities in an apartment , typically include electricity, water, gas, heating, and cooling.

The efficient utilization of these resources ensures a comfortable and convenient living environment, allowing tenants to enjoy a seamless and enjoyable tenancy.

Types of utilization

Utilization refers to the extent to which a resource, asset, or capacity is being used. Different types of utilization exist, each with its own significance in various contexts.

Resource utilization

Resource utilization measures the degree to which available resources are being employed. It encompasses various resources, such as raw materials, labor, capital, and time.

For instance, in manufacturing, resource utilization can be assessed by examining the efficiency of raw material usage. A high resource utilization rate indicates efficient use of resources, minimizing waste and maximizing productivity.

Capacity utilization

Capacity utilization evaluates the extent to which a system or facility is operating at its maximum potential. It is commonly used in manufacturing, transportation, and healthcare.

In a manufacturing plant, capacity utilization can be calculated by comparing the actual output to the maximum possible output. A high capacity utilization rate signifies that the facility is operating close to its full potential, maximizing production.

Equipment utilization

Equipment utilization measures the degree to which a specific piece of equipment or machinery is being utilized. It is particularly relevant in industries where equipment plays a critical role, such as construction, mining, and transportation.

For example, in a construction project, equipment utilization can be tracked to ensure that machinery is being used efficiently. A high equipment utilization rate indicates that the machinery is being deployed effectively, minimizing downtime and optimizing productivity.

Importance of utilization

Utilization is of paramount importance in various fields, including business, engineering, and healthcare. It enables organizations to make informed decisions, optimize resources, and achieve their goals effectively.

In business, utilization metrics help companies understand how efficiently they are using their assets, such as equipment, inventory, and human resources. By optimizing utilization, businesses can increase productivity, reduce costs, and improve profitability.

Engineering

In engineering, utilization is crucial for designing and operating systems efficiently. Engineers use utilization data to determine the capacity of a system, identify bottlenecks, and optimize performance. This information helps ensure that systems are operating at their optimal levels, reducing downtime and maximizing productivity.

Healthcare

In healthcare, utilization data is essential for managing resources and improving patient outcomes. Hospitals and clinics use utilization metrics to track patient visits, bed occupancy, and staff workload. By analyzing this data, healthcare providers can identify areas for improvement, such as reducing wait times, optimizing staffing levels, and improving patient satisfaction.

– Factors affecting utilization

Utilization rates are influenced by a range of factors, both internal and external to the system or process being evaluated. Understanding these factors is crucial for optimizing utilization and ensuring efficient resource allocation.

Factors affecting utilization rates can be broadly categorized into the following:

Demand and supply dynamics

Demand and supply dynamics play a significant role in determining utilization rates. High demand for a particular resource or service will naturally lead to higher utilization, while low demand can result in underutilization.

Resource availability

The availability of resources, such as equipment, personnel, or raw materials, can directly impact utilization rates. Limited resource availability can constrain utilization, while ample resources can facilitate higher utilization.

Process efficiency

The efficiency of the processes involved in utilizing resources can influence utilization rates. Inefficient processes can lead to bottlenecks and underutilization, while efficient processes can maximize utilization.

Capacity planning

Capacity planning involves forecasting demand and allocating resources accordingly. Accurate capacity planning can ensure that resources are optimally utilized, while poor capacity planning can result in either overutilization or underutilization.

External factors

External factors, such as economic conditions, industry trends, and technological advancements, can also affect utilization rates. Economic downturns can lead to decreased demand and lower utilization, while technological advancements can improve efficiency and increase utilization.

– Describe the different types of utilization metrics and their use cases

Utilization metrics are quantitative measurements that assess the extent to which a resource is being used. These metrics can be used to track the efficiency and effectiveness of a system, process, or asset. There are many different types of utilization metrics, each with its own specific purpose and use case.

Some of the most common types of utilization metrics include:

- Resource utilization: This metric measures the percentage of time that a resource is in use. It can be used to identify bottlenecks and areas where resources are being underutilized.

- Capacity utilization: This metric measures the percentage of time that a system is operating at its maximum capacity. It can be used to identify areas where the system is being overloaded and needs to be expanded.

- Throughput: This metric measures the number of units that can be processed by a system in a given period of time. It can be used to assess the efficiency of a system and identify areas where it can be improved.

- Utilization rate: This metric measures the percentage of time that a resource is actually being used for productive purposes. It can be used to identify areas where resources are being wasted and can be used more efficiently.

Utilization metrics can be used to improve decision-making in a number of ways. For example, they can be used to:

- Identify areas where resources are being underutilized or overloaded

- Plan for future capacity needs

- Improve the efficiency of a system

- Reduce costs

Improving utilization

Improving utilization rates is crucial for optimizing resources and enhancing organizational efficiency. Strategies for enhancing utilization include:

- Capacity planning:Analyze current and future demand to ensure optimal resource allocation.

- Workload management:Distribute work evenly to avoid underutilization and bottlenecks.

- Automation and technology:Leverage technology to automate tasks and free up resources for higher-value activities.

- Process optimization:Streamline processes to reduce waste and improve efficiency.

Industry benchmarks and insights

Industry benchmarks provide valuable insights into utilization rates and improvement strategies. By comparing performance against benchmarks, organizations can identify areas for improvement and set realistic targets. Exceeding industry benchmarks requires a combination of best practices, innovation, and continuous improvement efforts.

Key metrics for tracking utilization and improvement strategies

| Metric | Description |

|---|---|

| Utilization rate | Percentage of time resources are actively engaged in productive work. |

| Idle time | Percentage of time resources are not engaged in productive work. |

| Work in progress (WIP) | Amount of work currently being processed. |

| Throughput | Rate at which work is completed. |

Real-world examples of organizations improving utilization rates

- Example 1:Company A implemented a capacity planning tool that helped them optimize resource allocation, resulting in a 15% increase in utilization.

- Example 2:Company B introduced an automated workflow system that reduced manual tasks by 30%, freeing up resources for more strategic initiatives.

Step-by-step guide to implementing utilization improvement initiatives

- Assess current utilization:Measure utilization rates using relevant metrics.

- Identify improvement areas:Analyze utilization data to identify bottlenecks and underutilized resources.

- Develop improvement strategies:Implement best practices, technology, and process optimization techniques to enhance utilization.

- Implement and monitor:Implement improvement initiatives and track progress through key metrics.

- Continuously improve:Regularly review utilization data and make adjustments to optimize resource allocation and utilization rates.

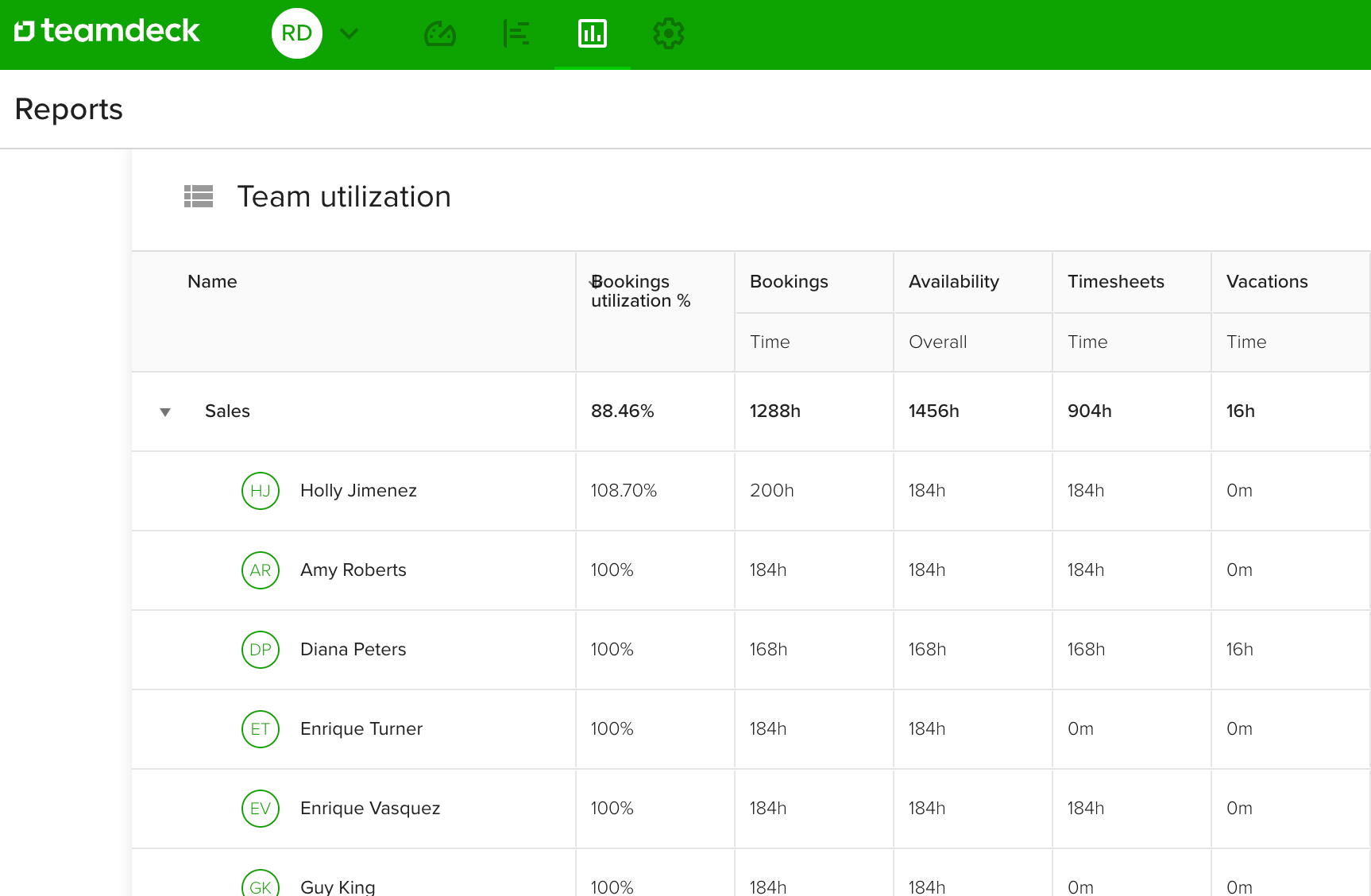

Utilization in project management

Resource utilization is a critical aspect of project management, referring to the efficient and effective use of available resources throughout the project lifecycle. It involves maximizing the productivity and output of resources, such as personnel, equipment, and materials, to achieve project objectives within the constraints of time, budget, and quality.Calculating resource utilization involves determining the percentage of time a resource is actively engaged in project activities.

This can be done by tracking actual hours worked against planned hours or using resource allocation tools. Optimizing resource utilization aims to minimize idle time and ensure resources are allocated to tasks that maximize their contribution to project outcomes.

Impact on project costs and timelines

Resource utilization directly impacts project costs and timelines. Efficient utilization reduces the need for additional resources or overtime work, leading to cost savings. Conversely, underutilization results in wasted resources and potential delays. Effective utilization helps ensure resources are assigned to critical tasks, reducing the risk of bottlenecks and delays, ultimately contributing to timely project completion.

Improving resource utilization

Improving resource utilization in project management involves several strategies, including:

Effective planning

Utilization, in the context of land use, refers to the practical use of a property for a specific purpose. This concept is closely related to utility easements, which grant a legal right to a utility company to use a portion of land for the installation and maintenance of infrastructure, such as power lines, pipelines, or telecommunications equipment.

Utility easements allow utility companies to access and utilize land without owning it, ensuring the provision of essential services while preserving the property rights of landowners. Understanding the concept of utilization and its connection to utility easements is crucial for managing land use and infrastructure development effectively.

Thoroughly planning project activities and resource requirements upfront can minimize underutilization and avoid overallocation.

Resource leveling

Smoothing out resource demand across the project timeline to avoid peaks and valleys in utilization.

Cross-training

Enabling resources to perform multiple tasks, increasing their flexibility and utilization.

Resource forecasting

Predicting future resource needs based on historical data and project projections, allowing for proactive adjustments.

Communication and collaboration

Establishing clear communication channels and fostering collaboration among team members can identify and address resource utilization issues promptly.

Utilization in manufacturing

Capacity utilization is a crucial metric in manufacturing, reflecting the efficiency with which a production system uses its available resources to generate output. High capacity utilization indicates that the system is operating close to its maximum potential, resulting in optimal production efficiency and reduced waste.

Conversely, low capacity utilization suggests underutilized resources, leading to inefficiencies and increased costs.

Measuring capacity utilization involves determining the ratio of actual output to maximum possible output. To improve capacity utilization, manufacturers can implement various strategies, such as optimizing production schedules, reducing downtime, and improving resource allocation. By maximizing capacity utilization, manufacturers can enhance productivity, reduce costs, and increase profitability.

Factors affecting capacity utilization

Several factors can influence capacity utilization in manufacturing, including:

- Demand fluctuations

- Equipment availability

- Labor productivity

- Process efficiency

- Raw material availability

Improving capacity utilization

Manufacturers can implement various strategies to improve capacity utilization, such as:

- Demand forecasting:Accurately predicting demand helps manufacturers plan production schedules and resource allocation to match demand fluctuations.

- Preventive maintenance:Regular maintenance reduces unplanned downtime and ensures equipment is operating at optimal efficiency.

- Process optimization:Streamlining production processes, reducing bottlenecks, and improving workflow can increase output and reduce waste.

- Resource allocation:Optimizing resource allocation ensures that resources are used efficiently and not underutilized or overloaded.

Benefits of improving capacity utilization

Improving capacity utilization in manufacturing offers numerous benefits, including:

- Increased productivity:Maximizing capacity utilization allows manufacturers to produce more output with the same resources.

- Reduced costs:Improved capacity utilization leads to lower production costs per unit and increased profitability.

- Improved customer satisfaction:Meeting demand efficiently reduces lead times and improves customer satisfaction.

- Increased flexibility:High capacity utilization provides manufacturers with the flexibility to respond to changing market conditions and demand fluctuations.

Utilization in healthcare

The healthcare industry relies heavily on medical equipment to provide optimal patient care. Efficient utilization of this equipment is crucial for enhancing patient outcomes and optimizing healthcare operations.

Optimizing equipment utilization involves several strategies, including regular maintenance, proper training of staff, and implementing automated scheduling systems. By maximizing equipment uptime and minimizing downtime, healthcare providers can ensure that patients have timely access to essential medical services, leading to improved patient satisfaction and reduced waiting times.

Cost reduction

Furthermore, efficient equipment utilization can significantly reduce healthcare costs. When equipment is used optimally, there is a decreased need for costly repairs or replacements. Additionally, optimized utilization can lead to reduced energy consumption and lower maintenance expenses, resulting in overall cost savings for healthcare facilities.

Improved patient care

Optimal equipment utilization directly translates into improved patient care. When equipment is available and functioning properly, healthcare professionals can provide timely and effective treatments, leading to better patient outcomes. Efficient utilization also ensures that patients have access to the latest medical technologies and advancements, contributing to enhanced quality of care.

Utilization in IT

In the IT realm, utilization pertains to the effective usage of computing resources, particularly servers, to maximize their performance and efficiency. Monitoring and optimizing server utilization is crucial for ensuring optimal system responsiveness, preventing bottlenecks, and reducing operational costs.

Server Utilization in IT

Server utilization measures the extent to which a server’s resources, such as CPU, memory, and network bandwidth, are being utilized. High utilization rates indicate that the server is approaching its capacity, while low utilization rates suggest underutilized resources.

Monitoring server utilization helps identify performance bottlenecks, plan for capacity upgrades, and optimize resource allocation. By understanding the utilization patterns, IT administrators can proactively address potential issues and ensure smooth operation of critical applications and services.

Monitoring and Optimizing Server Utilization

- CPU Utilization:Measures the percentage of time the CPU is actively processing tasks. High CPU utilization can lead to performance degradation and system slowdowns.

- Memory Utilization:Indicates the amount of physical memory being used. Insufficient memory can cause applications to crash or run slowly.

- Network Utilization:Measures the amount of data being transmitted over the network interface. High network utilization can result in network congestion and slowdowns.

Optimizing server utilization involves techniques such as:

- Load Balancing:Distributing workload across multiple servers to prevent overloading.

- Virtualization:Creating virtual machines to run multiple operating systems and applications on a single physical server.

- Capacity Planning:Forecasting future resource requirements and planning for upgrades accordingly.

Key Metrics for Measuring Server Utilization

| Metric | Description |

|---|---|

| CPU Utilization | Percentage of time the CPU is actively processing tasks |

| Memory Utilization | Percentage of physical memory being used |

| Network Utilization | Amount of data being transmitted over the network interface |

| Disk Utilization | Percentage of disk space being used |

| I/O Utilization | Number of input/output operations per second |

Best Practices for Optimizing Server Utilization

- Monitor server utilization regularly to identify performance bottlenecks.

- Implement load balancing techniques to distribute workload evenly.

- Use virtualization to consolidate multiple applications on a single physical server.

- Plan for capacity upgrades based on forecasted resource requirements.

- Consider cloud computing services for scalability and cost optimization.

Script to Monitor Server Utilization, What is utilization

Here’s a simple script using the sarcommand to monitor server utilization:

sar -u 1 5

This script will display CPU utilization every second for the next 5 seconds.

Utilization in supply chain management

Inventory utilization is a critical aspect of supply chain management, as it directly impacts efficiency, cost, and customer satisfaction. It measures the effectiveness of inventory management practices in meeting demand while minimizing waste and maximizing asset utilization.

Optimizing inventory utilization involves balancing supply and demand to ensure that the right amount of inventory is available at the right time and place. This can be achieved through various strategies, including demand forecasting, inventory control techniques, and collaboration with suppliers and customers.

Role of inventory utilization in supply chain management

- Reduced waste and spoilage:Efficient inventory utilization helps minimize waste and spoilage by preventing excess inventory that may become obsolete or deteriorate over time.

- Improved efficiency:Optimized inventory utilization allows for smoother and more efficient operations, reducing lead times, minimizing production disruptions, and improving overall supply chain performance.

- Enhanced customer satisfaction:By ensuring the availability of products when customers need them, optimized inventory utilization leads to increased customer satisfaction and loyalty.

Optimizing inventory utilization to reduce waste and improve efficiency

- Demand forecasting:Accurate demand forecasting helps businesses predict future demand and adjust inventory levels accordingly, reducing the risk of overstocking or understocking.

- Inventory control techniques:Implementing inventory control techniques, such as just-in-time (JIT) and safety stock management, helps optimize inventory levels and minimize waste.

- Supplier and customer collaboration:Collaborating with suppliers and customers can improve inventory visibility and coordination, enabling better demand planning and inventory management.

- Technology utilization:Utilizing technology, such as inventory management software and RFID tracking systems, can automate processes, improve inventory visibility, and enhance decision-making.

Utilization in finance

Utilization in finance refers to the extent to which a company effectively employs its assets to generate revenue. Asset utilization ratios are important metrics for assessing a company’s financial performance and efficiency. These ratios provide insights into how well a company is managing its assets and generating returns.

Asset Utilization Ratios

Asset utilization ratios measure the efficiency of a company’s asset management. Common ratios include:

- Asset Turnover Ratio:Measures how efficiently a company generates sales from its assets. Calculated as Net Sales / Average Total Assets.

- Fixed Asset Turnover Ratio:Measures how effectively a company utilizes its fixed assets. Calculated as Net Sales / Average Fixed Assets.

- Inventory Turnover Ratio:Measures how quickly a company sells its inventory. Calculated as Cost of Goods Sold / Average Inventory.

Interpreting these ratios involves comparing them to industry benchmarks or historical data. Higher ratios generally indicate better asset utilization and efficiency.

Utilization in human resources

Employee utilization in human resources refers to the extent to which employees’ skills, knowledge, and abilities are being used effectively to achieve organizational goals. It involves optimizing the workforce to ensure that employees are working on the right tasks, at the right time, and with the right resources.

Measuring employee utilization is crucial for identifying areas of underutilization or overutilization. Common metrics used include:

- Capacity utilization:Measures the percentage of time employees are actively engaged in productive work.

- Workload utilization:Assesses the balance between employee workload and capacity.

- Skills utilization:Evaluates the extent to which employees’ skills are being utilized in their current roles.

Improving employee utilization requires a multifaceted approach, including:

- Workforce planning:Ensuring the right number and mix of employees with the necessary skills are available to meet business needs.

- Job design:Optimizing job roles to ensure they are challenging, engaging, and aligned with employee skills.

- Performance management:Regularly assessing employee performance and providing feedback to identify areas for improvement and utilization optimization.

- Training and development:Investing in employee training to enhance skills and increase utilization.

By effectively managing employee utilization, organizations can optimize workforce productivity, reduce costs, and improve employee engagement and satisfaction.

Utilization in sustainability

Utilization in sustainability refers to the efficient and responsible use of resources to minimize environmental impact and promote sustainability. This involves understanding the environmental consequences of resource consumption and implementing strategies to reduce waste and promote conservation.

Measuring resource utilization

Measuring resource utilization is crucial for understanding the environmental impact of human activities. Key metrics include:

- Energy consumption: Measuring the amount of energy used from various sources, such as electricity, natural gas, and transportation.

- Water consumption: Tracking the amount of water withdrawn from sources such as rivers, lakes, and groundwater.

- Material consumption: Quantifying the amount of raw materials used in production and consumption, including metals, plastics, and wood.

- Waste generation: Monitoring the amount and types of waste produced, including solid waste, wastewater, and hazardous waste.

Reducing resource utilization

Reducing resource utilization is essential for promoting environmental sustainability. Strategies include:

- Energy efficiency: Implementing measures to reduce energy consumption in buildings, transportation, and industrial processes.

- Water conservation: Adopting practices to reduce water usage, such as efficient irrigation systems and rainwater harvesting.

- Material recycling and reuse: Encouraging the reuse and recycling of materials to minimize waste and conserve resources.

- Waste reduction: Implementing waste reduction programs, such as composting, recycling, and reducing packaging.

By understanding and reducing resource utilization, organizations and individuals can contribute to environmental sustainability and mitigate the impact of human activities on the planet.

Essential FAQs

What are the different types of utilization?

There are various types of utilization, including resource utilization, capacity utilization, equipment utilization, and employee utilization.

Why is utilization important?

Utilization is important because it helps organizations and individuals optimize their resource usage, reduce costs, and improve productivity.

What factors affect utilization?

Factors that affect utilization include resource availability, demand, process efficiency, and external factors such as economic conditions.